A solid-state battery isolator is an electronic device used to manage and distribute electrical power between multiple batteries and a single charging source, such as an alternator, in vehicles, RVs, boats, or other systems. Unlike traditional mechanical or diode-based isolators, a solid-state battery isolator uses semiconductor components to achieve this. Here’s a detailed explanation of how it works:

Components:

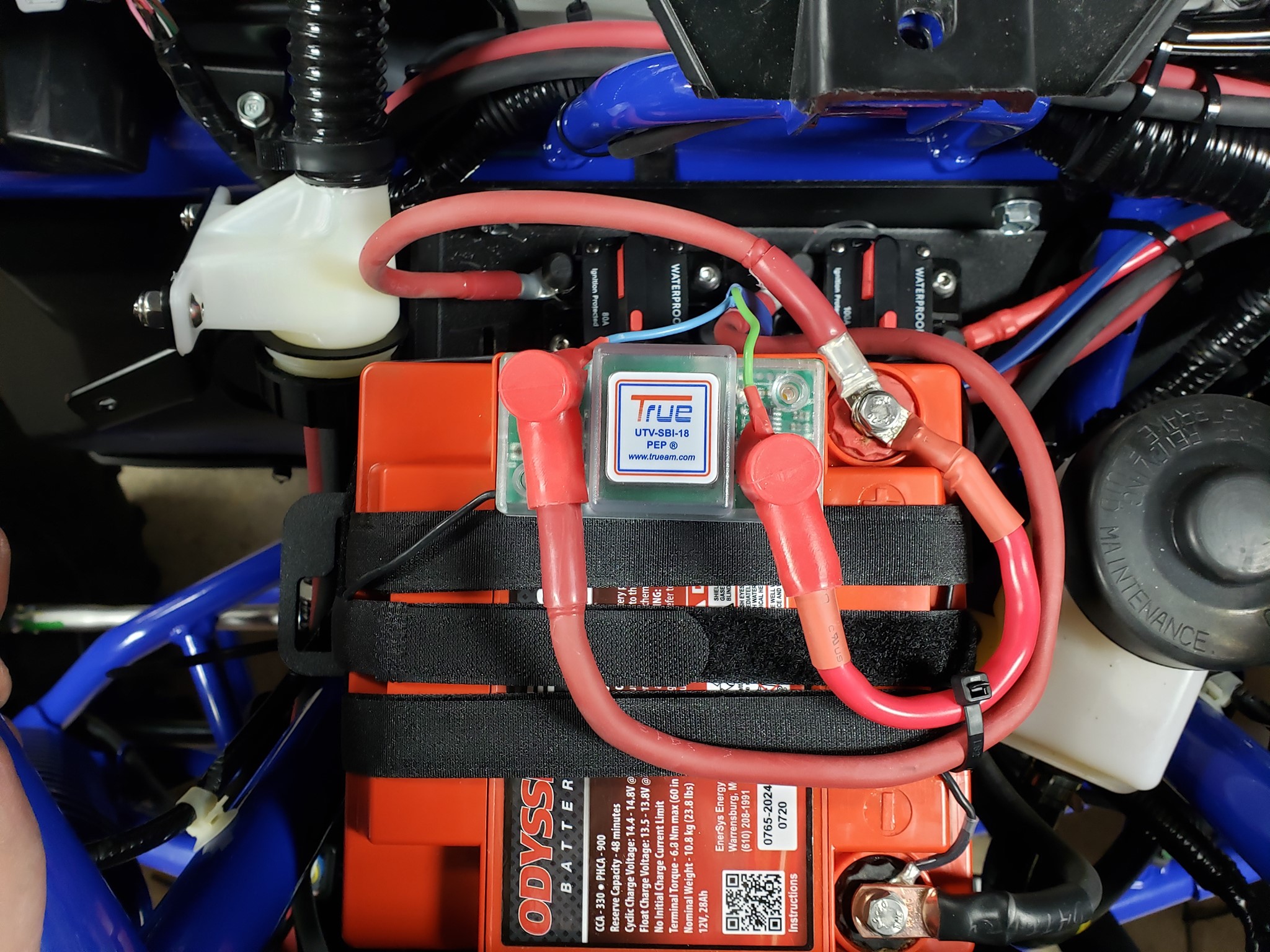

- Semiconductor Switches: Typically transistors or MOSFETs that control the flow of electrical current.

- Control Circuitry: Monitors the voltage levels of the batteries and controls the operation of the semiconductor switches.

- Heat Sink: Dissipates heat generated by the semiconductors during operation.

- Input Terminal: Connects to the power source, such as an alternator.

- Output Terminals: Connect to the batteries that need to be managed and charged.

Working Principle

Voltage Monitoring

- The control circuitry continuously monitors the voltage levels of the primary (starting) battery and the auxiliary battery(ies).

- When the engine is running and the alternator is generating power, the control circuitry detects an increase in voltage from the primary battery.

Current Distribution

- Once the control circuitry detects a sufficient charging voltage, it activates the semiconductor switches.

- The semiconductor switches then direct the current from the alternator to both the primary and auxiliary batteries, allowing them to charge simultaneously.

- The solid-state isolator ensures that each battery receives the appropriate amount of charge based on its needs.

Isolation

- When the engine is off and the voltage drops, the control circuitry detects this change.

- The semiconductor switches are then deactivated, isolating the batteries from each other.

- This prevents the auxiliary battery from draining the primary battery, ensuring that the primary battery retains enough charge to start the engine.

Advantages

- Efficiency: Minimal voltage drop across the semiconductor switches ensures efficient charging.

- Durability: No moving parts, reducing wear and increasing longevity.

- Reliability: Provides consistent performance without the risk of mechanical failure.

- Compactness: Typically smaller and lighter than mechanical isolators.

- Heat Management: Often includes features to manage heat generation effectively.

- Battery Protection: Prevents the discharge of one battery into another, maintaining the health of each battery.

Example Scenario

In a dual-battery system in an RV:

- When the RV engine is running, the alternator charges both the starting battery and the auxiliary (house) battery via the solid-state isolator.

- When the engine is turned off, the solid-state isolator ensures that the starting battery is isolated, so it remains fully charged and ready to start the engine, while the auxiliary battery can be used to power appliances and lights in the RV.

In summary, a solid-state battery isolator uses semiconductor components to efficiently manage the charging and isolation of multiple batteries, providing a reliable and efficient solution for dual-battery systems.